Managers in the reagent industry often face headaches due to the large amount of product, customer, and supplier data, frequent changes in supplier product inventory and price information, troublesome updates, large order volumes, complicated inbound and outbound processes, tedious invoicing and reconciliation workloads, and high error rates. Traditional ERP systems, which pursue full industry customer coverage, abandon industry characteristics, and strive for universality, cannot solve the difficulties and pain points of reagent and consumables enterprises.

We have conducted extensive research on customer characteristics in the reagent, instrument, and consumables industries, and developed a warehouse price ERP management system based on the actual work situation of customers. This system only serves the biochemical industry and has been continuously upgraded and updated over the years, which is very suitable for various application scenarios of industry customers.

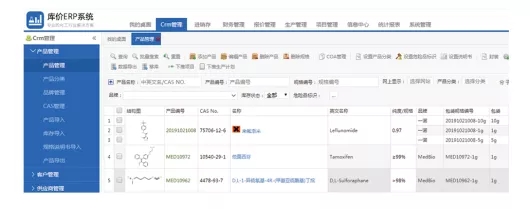

Product specialization management

The system can conveniently manage the different purities, brands, specifications, prices, and corresponding inventory of a compound, and accurately control COA, spectra, storage locations, and costs for different batches of compound inventory.

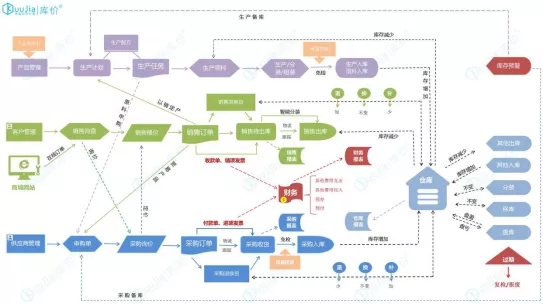

Intelligent inventory management system

Realize integrated full process tracking and management of sales inquiries, quotations, orders, procurement requisitions, inquiries, orders, warehouse receipts and shipments, logistics tracking, financial receipts and payments, invoicing, etc; Realize data linkage, reconciliation and verification.

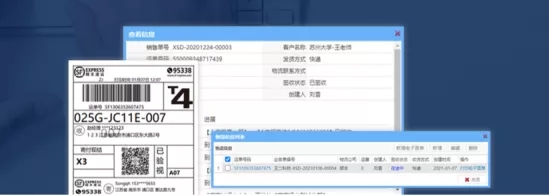

Thoughtful document and label output printing

The system supports the printing of documents required for various aspects of company business management, supports custom printing templates, and automatically generates data content, such as sales quotations, order contracts, delivery notes, labels, etc.

Production management

Suitable for reagent packaging, product mixing, instrument assembly, consumables production, etc. Support product formula declaration form, support production planning, production tasks, related raw material procurement, use, production testing, material return, cost accounting, etc.

Logistics automatic docking, SMS notification, electronic signature form

Coordinate with logistics companies, automatically generate electronic waybills, and obtain real-time logistics progress and update delivery status; Real time monitoring of consignment inventory and real-time tracking of pending logistics status; Delivery note/delivery note signature status, electronic signature design; Notify users of shipping logistics SMS and sales invoice logistics SMS.

Some classic cases

We will continue to work together with everyone to provide reliable technology and product support for the digital transformation of enterprises in the chemical, biological, and pharmaceutical industries.

We believe in software as a service, and software should improve work efficiency. Development and users are the best driving forces for product upgrades. Looking forward to your business inquiries and cooperation.